Area Clearance Roller

Area Clearance Roller

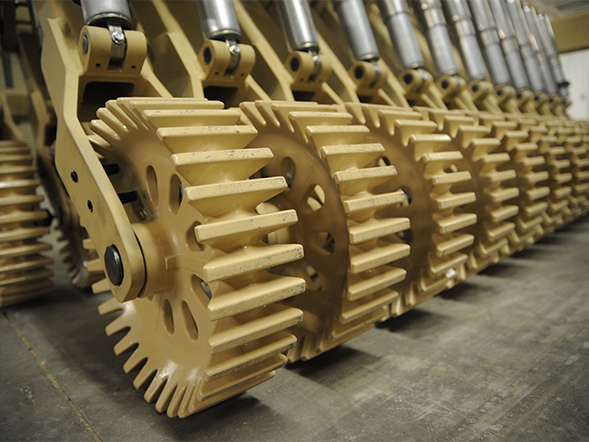

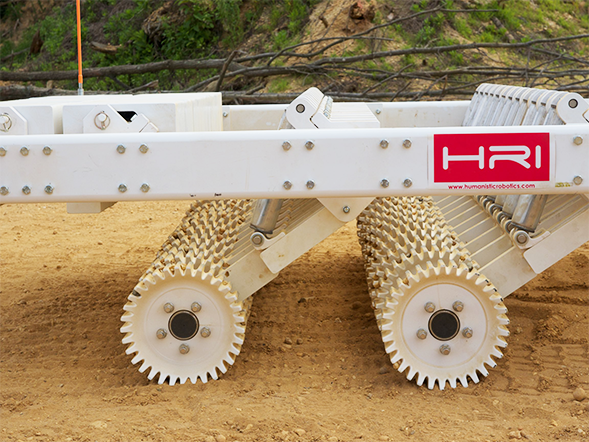

In designing the Area Clearance Roller, HRI first looked under the surface of the soil to see what it would take to trigger mines with a roller. In simulated minefields, HRI engineers measured mine roller ground force in different soils, compaction levels, speed, weight, and depth, and used the data to set technical specifications for the roller. With these specifications, the Area Clearance Roller was designed literally from the ground up to deliver more than the minimum ground force levels required to hit AP mines.

The Area Clearance Roller’s suspended swing arm array allows the user to vary the weight and width according to conditions and vehicle requirements. Swing arm and roller wheel replacement can be done in minutes, meaning field maintenance and shipping are cheap, fast, and easy.

Area Clearance Roller Features

- Increased performance through consistent ground coverage

- Can be used for technical survey, area reduction, QA/QC, proofing, confidence building

- Over 99% accuracy in third party tests

- Quick assembly and breakdown to minimize logistics requirements

- Simple repairs and maintenance using COTS parts and modular design increases operational efficiency

- Highly survivable against explosive targets, continued use after detonation